Hot News

Newsletter Downloads

News

-

LYC's testing capability improving continuously

Press release on October 16th in recent years LYC focused on improving the testing capability and analysis level,as well as actively paying close attention to international advanced technology in the testing field of bearing industry and purchasing advanced testing equipments which provide our co...

Oct,16,2009

-

LYC new overhaul line for high speed railway bearings was certificated by MOR

On October 14th LYC new overhaul line for high speed railway bearings gained the production quality certification from the expert group of MOR.

Oct,14,2009

-

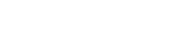

LYC’s slewing bearing division take delivery of new forging equipment

September 18thThis is part of the program for LYC’s technological transformation project. LYC’s slewing bearing division has installed a new 2500T hydraulic press with the capacity to roll up to 4 Meters in diameter. This equipment allows for a forging range from 1.6 meters to 4 meters. The equi...

Sep,18,2009

-

LYC Computer-Aided Process Planning (CAPP) now in operation

September 18thOne of LYC’s key research projects CAPP has now been fully integrated. It began in April 2008; this CAPP was applied in the design of taper roller bearings in August this year and is proving to be very successful. The system enables the designers to reduce design time with the net r...

Sep,18,2009

-

LYC intensive & extensive capital investment for the future

September 11thOver 1 billion RMB will be invested into LYC industries this investment will focus on upgrading all 6 major divisions:1) The rail transit bearing project represented by 350km/h high speed CRH bearing.2) The wind turbine 3rd bearing project represented by gear box bearing.3) The new v...

Sep,11,2009

-

Full speed ahead for LYC to implement their new product developments

August 21stLYC have speeded up their new product developments. During the first half of 2009 new product developments achieved 84% increase and design grew 83% compared to the same period last year. New product developments have been focused in the fields of wind turbine automobile rolling mill pr...

Aug,21,2009

-

Major development in heat treatment quenching and temppering processes for wind turbine bearings

August 17thLYC have achieved major progress in their quenching and tempering for the heat treatment of wind turbine bearings. Their process flow has improved the low temperature impact efficiency. The result of this process will allow the performance index to far exceed the wind turbine bearing st...

Aug,17,2009

-

LYC successfully developed epbs main bearing

July 29thLYC successfully developed EPBS (Earth Pressure Balance Shield) main bearing. The main contributing factors to this bearing’s success were dependent on the extensive development work in LYC’s heat treatment process and their ability to resolve issues in the area of mid frequency inducti...

Jul,29,2009

-

The installation of advanced detectors at lyc’s heat treatment plant

July 17thLYC’s heat treatment plant installed 4 new sets of magnetic particle detectors for applications in ring forgings; this will further enhance LYC’s quality control. This type of equipment not only adjusts automatically the electric power according to different bearing dimensions but will ...

Jul,17,2009

-

LYC purchase international advanced analysis instrumentation

July 17thLYC import several advanced analysis instruments these include a Alloy Analyzer from the USA X-Ray Stress Analyzer and Bearing Grinding Burn Analyzer from Finland Metallographic Microscope & Image Analysis System from Japan etc. The acquisition of these types of instrumentation show LYC’...

Jul,17,2009