Electric Motor

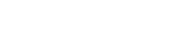

Motor, used as power source in all industries.LYC Bearings widely used in transmission parts of motors, LYC bearings support the smooth and quiet rotation, at the same time, carry a significant role into bearing the loads of motors.

Under the close cooperation with product development engineer, we developed techniques of optimizations and more economic bearing concepts for a new generation motor.LYC experienced application engineer selected the optimal bearing dimension, interval, lubrication and sealing method according to different requests and make a further optimization for standard bearings.

Features

1.High Speed, long lifetime, lower noise, energy-consuming reduction

2.Through product design, advanced material and production technology, verify that our product have the characteristic of high reliability and long lifetime.

3.Due to special bearing project and light-weight design, reduced energy consumption. with space saving project, improved the power density.

Edge

1.LYC possessed domestic first-rate motor bearing automation production line, advanced technology, well-equipped, 60m/s high speed grinding device, improved the grinding efficiency;With AC servo constant power grinding control system, improved the control accuracy of grinder. Complete in monitoring methods, production lines assembly with high-precision roughness, groove type, roundness measuring instrument. Being able to produce P2,P4,P5,P6 kinds of precision bearings and Z1,Z2,Z3 low noise deep groove ball bearing. LYC product widely used in machine spindle, home appliances, automobile, motor market. Product can meet the special requirements of high-precision bearings, low vibration, low noise for end user.